Engineering Seal Strip: An Essential Component for Industrial Equipment and Components

Date:

17 Feb,2024

Engineering seal strips play a crucial role in the industrial equipment and components industry, specifically in the field of sealing materials and components. These strips provide the necessary sealing properties to ensure the proper functioning of various equipment and prevent leakage or contamination. In this article, we will explore the key aspects of engineering seal strips, their applications, and the advantages they offer.

Introduction:

Engineering seal strips play a crucial role in the industrial equipment and components industry, specifically in the field of sealing materials and components. These strips provide the necessary sealing properties to ensure the proper functioning of various equipment and prevent leakage or contamination. In this article, we will explore the key aspects of engineering seal strips, their applications, and the advantages they offer.

1. What are Engineering Seal Strips?

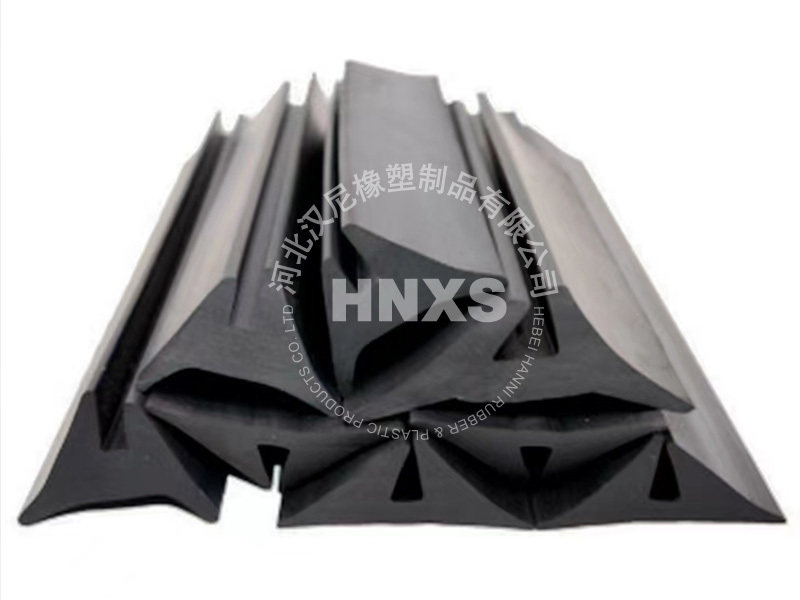

Engineering seal strips are flexible bands or tapes made from high-quality materials such as rubber, silicone, or foam. They are designed to create a secure seal between two surfaces, preventing the ingress or egress of unwanted substances like air, water, dust, or chemicals. These strips are commonly used in industries requiring airtight and watertight sealing solutions.

2. Applications of Engineering Seal Strips:

Engineering seal strips find extensive applications across diverse industries, including:

- Automotive: Seal strips are used in car doors, windows, trunks, and hoods to prevent noise, vibration, and water leakage.

- HVAC systems: These strips provide insulation and seal gaps in air conditioning ducts, preventing energy loss and ensuring efficient airflow.

- Electrical enclosures: Seal strips help maintain electrical enclosure integrity, protecting sensitive components from moisture, dust, and other contaminants.

- Aerospace: Seal strips are utilized in aircraft doors, windows, and compartments to ensure airtightness and temperature control.

- Manufacturing and machinery: Seal strips are employed in machinery and equipment to prevent leaks, reduce noise, and enhance operational efficiency.

3. Benefits of Engineering Seal Strips:

- Sealing Performance: Engineering seal strips offer excellent sealing performance, maintaining a tight and secure seal between mating surfaces.

- Enhanced Safety: By preventing leaks, seal strips ensure the safety of workers, equipment, and the environment, particularly in industries dealing with hazardous substances.

- Noise and Vibration Reduction: These strips absorb vibrations and reduce noise transmission, contributing to a quieter and more comfortable working environment.

- Energy Efficiency: By sealing gaps and preventing air leakage, seal strips help improve energy efficiency, reducing heating and cooling costs.

- Versatility and Durability: With various material options available, seal strips can be customized to suit specific environmental conditions, ensuring longevity and reliability.

In conclusion, engineering seal strips are indispensable components in the industrial equipment and components industry. Their versatile applications and numerous benefits make them vital for ensuring airtight and secure seals, preventing leaks, reducing noise, and enhancing safety and efficiency. By choosing high-quality engineering seal strips, industries can optimize performance, prolong equipment lifespan, and minimize maintenance costs.

Keywords: