Engineering Seals

The company has EPDM production line, rubber and plastic molding production line, plate vulcanizing machine, extrusion machine and other equipment, complete testing means, the formation of raw material preparation, mold development, product molding flow production mode, product quality to a high level.

Keywords:

Category:

产品附件:

Engineering Seals

图文详情

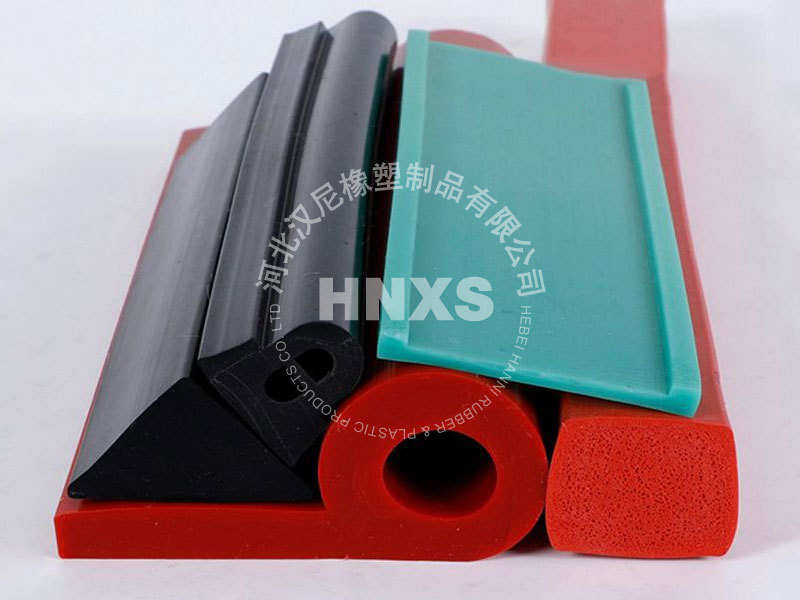

Types of Engineering Seals:

Compression Seals: Compression seals are the most common type of engineering seals. They utilize axial force to create a tight seal between the rotating and stationary parts. These seals typically consist of a rotating seal face and a stationary seal face that come into contact when the equipment is in operation. The faces are pressed together using springs or other mechanisms, generating enough pressure to prevent leakage.

Cartridge Seals: Cartridge seals are pre-assembled units that simplify the installation and replacement process. They consist of all the necessary components, including the seal faces, springs, and gland plates, enclosed in a cartridge housing. Cartridge seals offer advantages such as reduced installation time, improved reliability, and standardized designs that ensure consistent performance.

Gas Seals: Gas seals are designed for high-pressure applications where traditional compression seals may not be suitable. These seals use a gas, such as nitrogen, as the sealing medium. The gas forms a barrier between the rotating and stationary parts, effectively preventing leakage even under extreme operating conditions. Gas seals are commonly used in compressors and turbines.

Bellows Seals: Bellows seals are specifically designed to accommodate axial movement between the rotating and stationary parts. They feature a flexible bellows element that allows for axial, as well as some radial, movement. This flexibility helps compensate for thermal expansion, vibration, and other dynamic forces, ensuring a reliable and leak-free seal.

Previous

Next

上一页

Engineering Seals

Related Products

Product Inquiry